-40%

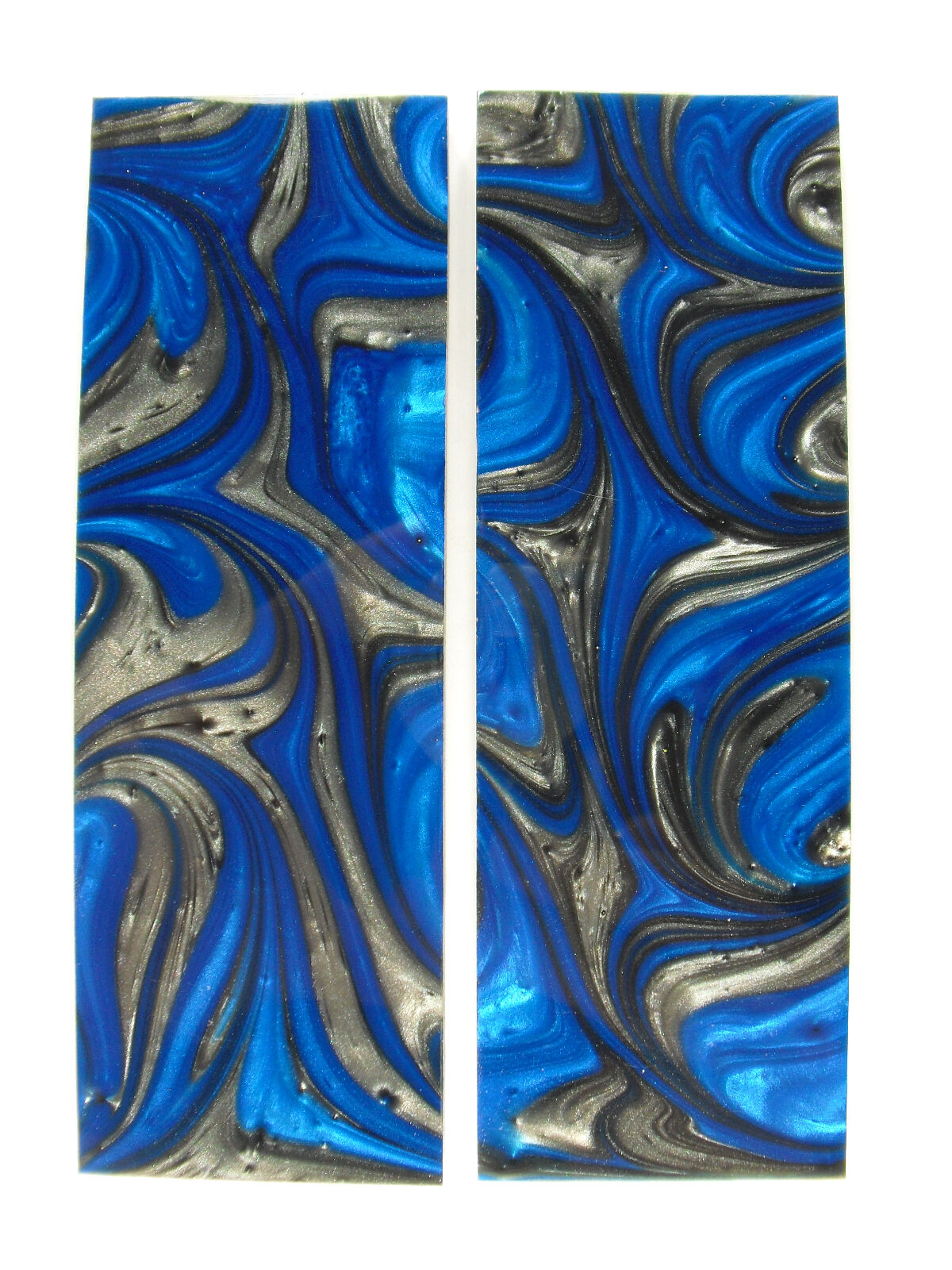

STABILIZED Cedar & Resin Knife Scales “Golden Wave” 5x2 inch by 3/8th inch Thick

$ 7.12

- Description

- Size Guide

Description

This is for a pair (2 total pieces

) of Stabilized

Cedar in the

“

Golden Wave

”

style

. These are STABILIZED (impregnated)

wooden

knife handles (Scales). They roughly measure 5”x 2” and are 3/8th inch thick

, usually a bit thicker

.

I start these at 5-1/4 inches long, by 2-1/4 inches wide and 1/2 thick and sand and plane them down from there so usually they run just a bit bigger then 5”x 2”. I try to provide you with the most material possible to allow for any errors while you are shaping, as well as allowing handle room for those of us with big paws. I can make these bigger or smaller, thinner or thicker upon request.

These scales are made from beautiful hand-selected Cedar grown, milled and cut in western Kentucky. I use dyed Resin (epoxy) for the White, Turquoise and Gold Marbled effect, and also heat activated Stabilizing Resin (the very popular and well preforming Cactus Juice) in making these scales. These are gorgeous Knife handles and will set your knifes apart from the rest!

ALL OF THE THESE SCALES HAVE BEEN STABILIZED. If you are unfamiliar with wood stabilization; Stabilizing wood is very very important, especially for wood that is being u

sed as a knife handle

. Stabilizing helps prevent the wood from expanding and contracting in various temperatures and humid environments. I

f you’ve even seen an older knife with cracks in the handle or seems to no longer fit exactly, that is why.

Non-Stabilized knife handles will move and crack over time during changing Atmospheric conditions.

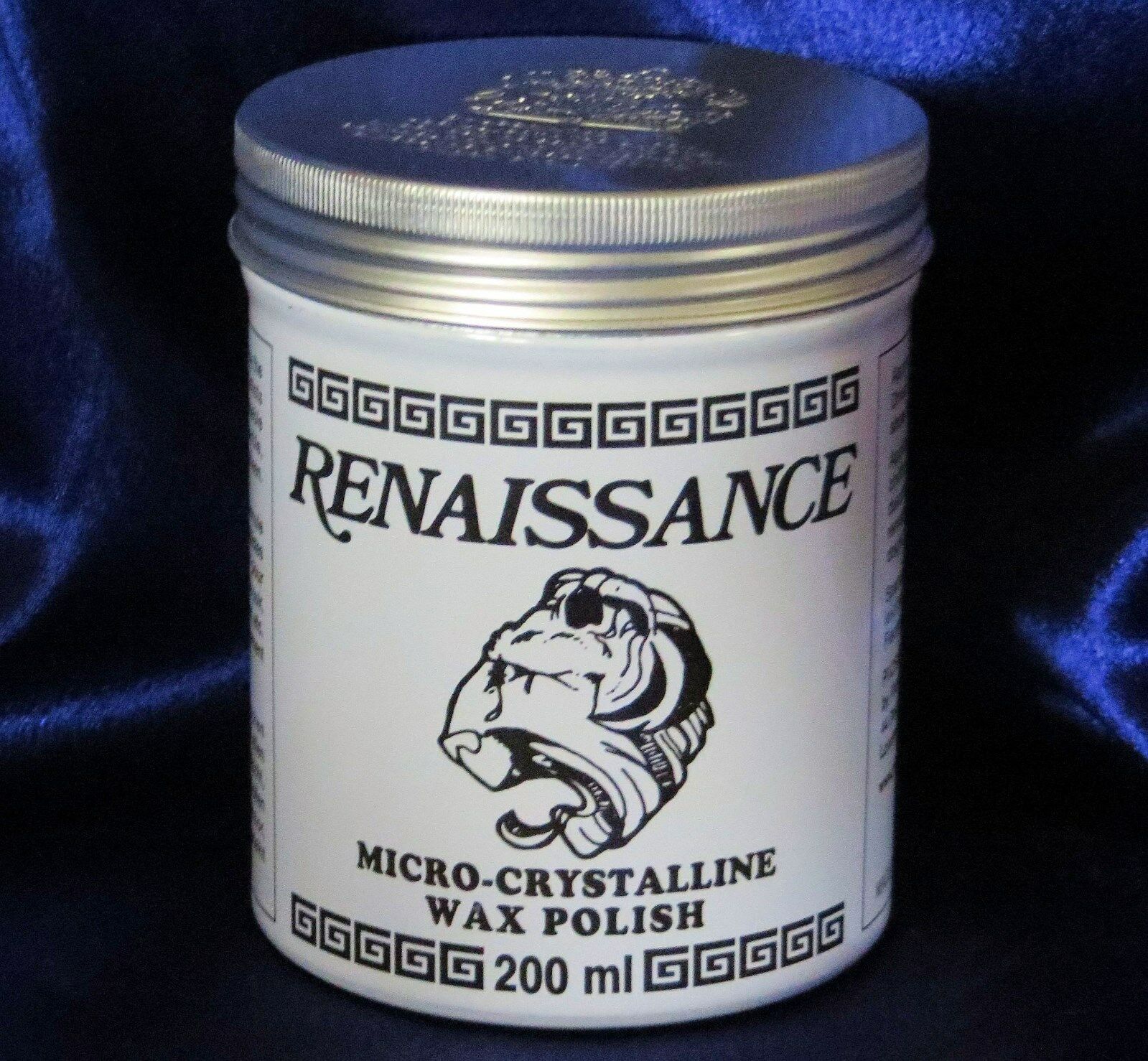

Stabilizing prevents that from happening. Stabilizing take a lot of equipment and the juice it’s self cost around 0 per gallon, but it makes very durable scales. If you are familiar with this process you can skip the next paragraph, but for those who are not:

T

he wood is

placed in a vacuum chamber. The

y are then

submersed in a special type of thin viscosity resin t

hat is later hardened

h

eat by heat.

The vacuum

draws

the air out of

the pores

in the wood. Since they are submerged in resin, the resin gets

sucked

into and fills the small pores and a

ny

gaps

, cracks

o

r natural weak points

inside of the wood. When the vacuum process is completed, t

he vacuum is let off and

the scales are left to soak for several hours. This is a VERY important part that is overlooked by m

any folks who

stabilize

or claim to stabilize wood

. Once that stage is over, they are placed in a oven and heated to at least 220°F for an hour or however long is needed, contingent of thickness. This causes the impregnated resin inside of the wood to harden, thus solidifying the once porous wood into a fixed hardened knife handle that’s extremely durable and will last for generations to come.

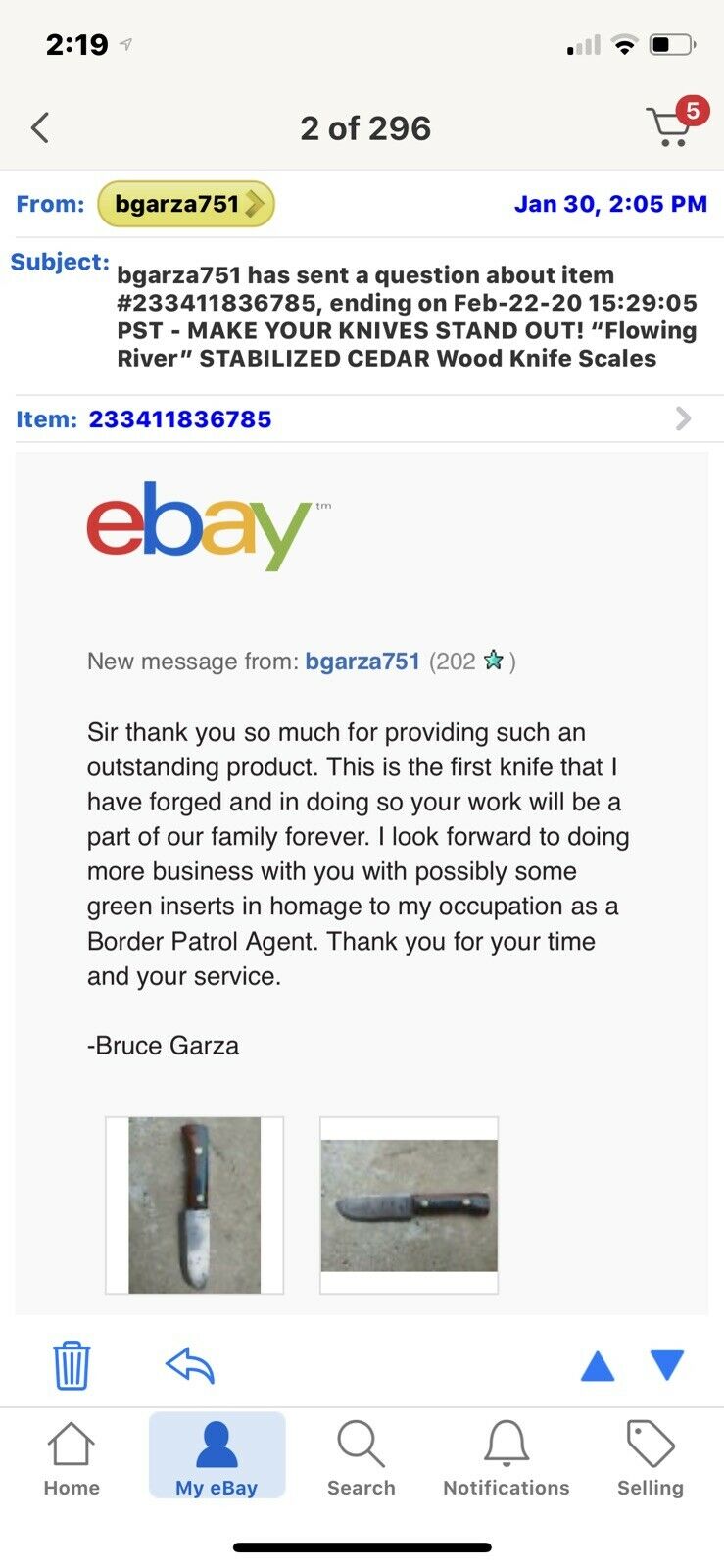

N

OTE:

The photos

displayed on

this auction

will

not be the exact blanks you received but will be very similar as I have made h

undreds of

pairs and have not photographed them all.

There is a lot of time and steps that go into making these scales

that many makers skip. These are made right

and the quality shows.

If you are interest in buying several pairs, feel free to message me for a price quote. I have many different styles and colors of scales on eBay so please feel free to look at my other auctions as well. I will combine shipping.

I appreciate you taking the time to read about the scales I make and I hope they find a home on your knife.

T

hank you.

-Dan